Testing

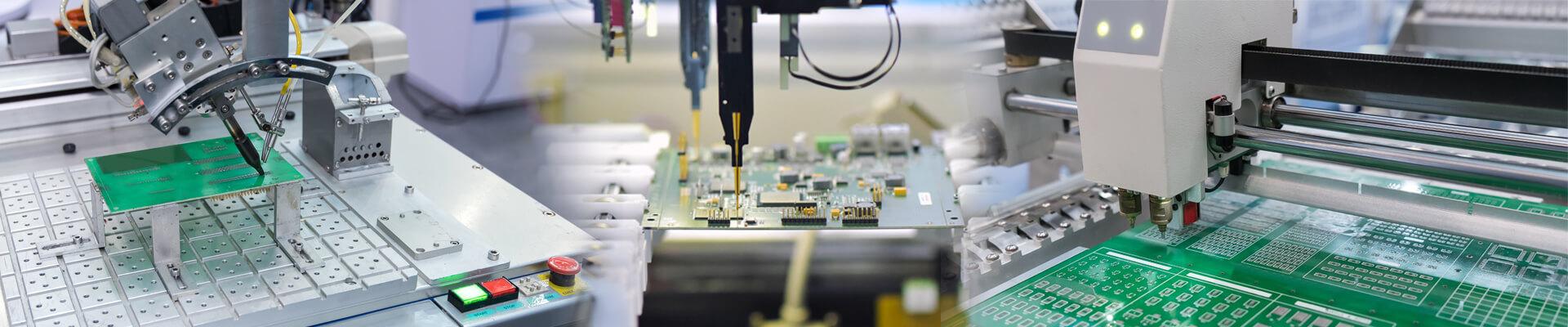

The final test of the modules with a function and end test is carried out by qualified specialist personnel. The standard processes and systems include:

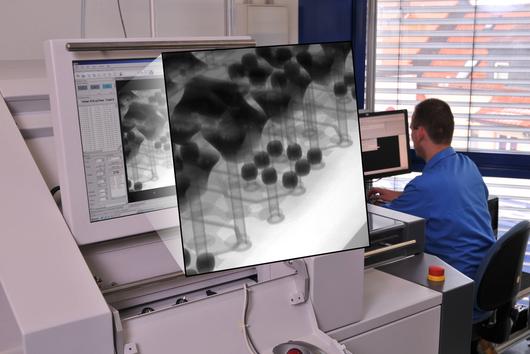

- automatic X-ray (AXI) and optical control systems (AOI)

- traceability systems using an Nd:YaG laser

- testing with a GenRad in-circuit tester and the Dr. Eschke test system

- function and end test incl. setting up the test equipment

- static and dynamic testing in temperature and climate chambers

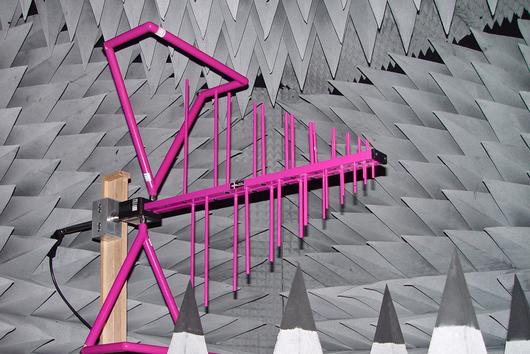

- professional HF-range testing using our product-related experience

- testing in our in-house HF screening chambers (damping up to 20 GHz / max. 100 dB)

- complete EMC preview

- multi-function absorber room

- for antenna measurements in a reflection-free or poor environment

- measurement of emissions (EMC/HF) / immunity and interference resistance tests, including for EMC measurements which accompany developments

- pre-compliance measurements (clarification of any problems before testing in the test laboratory)

Technical equipment used for our quality tests

- X-ray control systems (AXI)

- optical control systems (AOI)

- IC test

- function test

- climatic tests (+180°C to -40°C)

- vibration test

- absorber room

- in-house test and measuring equipment department

Device manufacturing and test work

- 3D product development

- 3D prototype construction (Fused Deposition Modeling, vacuum casting, selektive laser sintering, stereo lithograpy)

- Manufacture of samples

- Approval tests

- Tool production

- Series manufacture

- Test work and hardness tests (tightness, EMC characteristics, impact resistance)