Custom-designed enclosures – from the idea to series manufacture!

We manufacture enclosures according to your individual specifications and choice of manufacturing process!

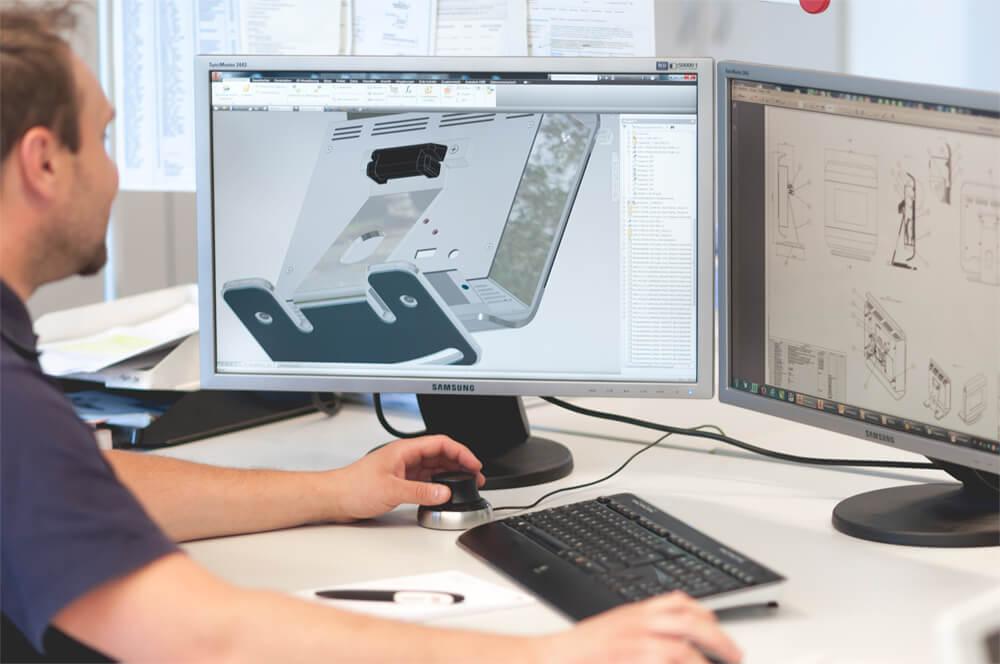

For many years, manufacturing custom-designed enclosures and components using different materials and processing methods has been part of our range of services and products. In addition, and on request, we manufacture prototypes for fault-analysis and very small runs for field tests. To a large extent, the choice of manufacturing process depends on the type and use of your enclosure and on the batch size. For example, we can produce prototypes quickly and at low cost, but making a special injection or die-cast tool is only worthwhile for larger quantities.

Your benefits:

- Unlimited design opportunities – the optimal manufacturing process for every requirement

- Enclosure designs which exactly match your electronics and components. You never need to compromise!

- Everything provided from a single source – we supply you with the functional terminal

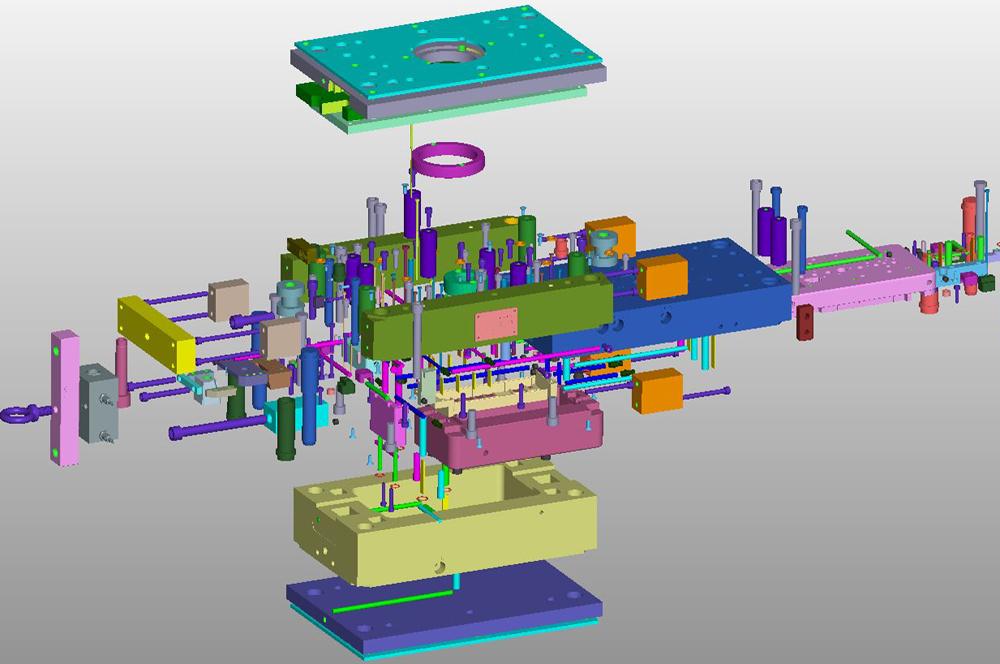

The right manufacturing process

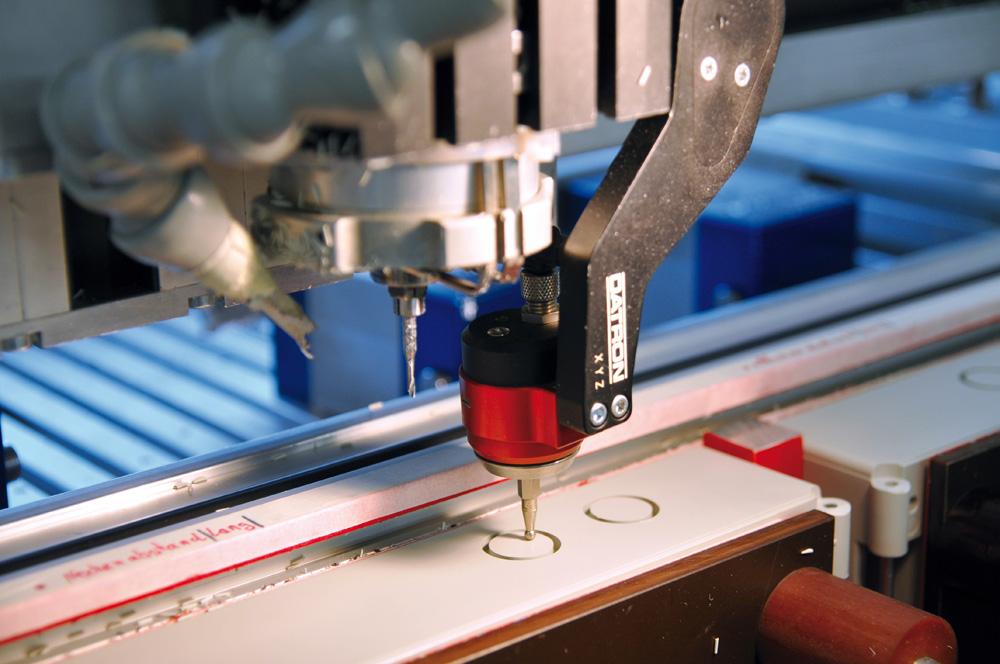

When selecting the right manufacturing process, the type and use of the enclosures, and also the series run, play important roles. The plastic injection moulding system provides a great deal of design freedom. The use of different surfaces can create eye-catching designs such as a polished logo. Diecast enclosures are ideal for use in harsh environments – the robustness of the material ensures that they stand out, and the material itself also creates an especially high-class impression for the user.

Profile enclosures are used when good heat dissipation and variability of length are required. Individual enclosure sizes can be created simply by cutting the profiles to the required length. There is also a solution when smaller quantities are required. Individual enclosures can be produced using stamping and bending technology – quickly, efficiently, and often without any investment costs. A wide range of materials is available, from aluminium to stainless steel. In addition, almost every surface design is possible.

Custom-designed enclosures – examples of applications

Here is a small selection of customers’ projects which have already been implemented. Whether plastic injection-moulding, aluminium die-casting or bent sheet metal technology are best – working together with you, we determine the optimal manufacturing process for your application.

Would you like to have general information on the subject of custom-designed enclosures?

We look forward to hearing from you in writing or by phone!

Ask about a custom-designed enclosure for your project!

Do you have a specific project with existing details? Then we look forward to receiving your inquiry on this form!