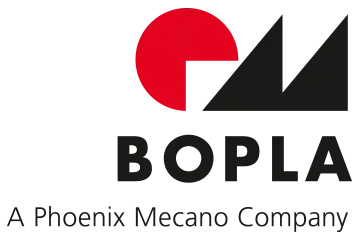

Capacitive membrane keypads for high mechanical loads

BOPLA is adding capacitive membrane keypads to the range of input units. These keypads are resistant to acids, dirt and other impurities, and are suitable for high mechanical loads. The surface is easy to clean, ensuring optimal standards of hygiene.

Detailed description of product

There is no mechanical connection to the operator, so the keys are not mechnical. The activating element is separated from the operator by means of a smooth surface, e.g. glass, plastic or another kind of non-conductive surface. This ensures that it is easy to clean the surface, so the device can be used in places which are at risk of vandalism, and also in hygienically clean environments, e.g. the medical and foodstuff sectors. In addition, the smooth surface guarantees that it is possible to operate the device without pressure – a light touch is sufficient. Visual and/or acoustic signals can compensate for the lack of tactile feedback. Keypads and switches which operate on the capacitive principle can be set up as individual keys o ras arrays, so any shape of key is possible, including individual layout designs.

Technical implementation

The sensor surface of the key consists of two sections which are insulated from each other (transmitting and receiving electrode). On the transmitting side, vibrations are generated which are transferred to the receiving electrode by means of capacitive coupling. When the finger comes into contact with the key surface, the capacity of the human body is switched into the receiver. The transmitting signals are damped, and switch impulses are detected and evaluated. Digital filters and specially adapted algorithms ensure that both short spurious signals and slow changes (rain, mist etc.) cannot result in any malfunctions.

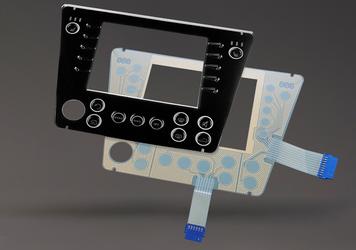

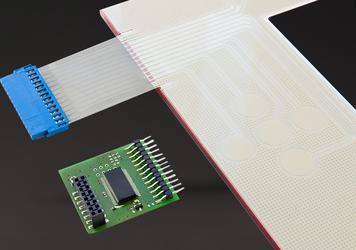

Different design versions

The complete capacitive operating unit consists of three elements: capacitive sensors, evaluating electronics, and the actual operator surface (normally glass or plexiglass). In many cases, the sensors and the evaluating electronics are placed on the same PCB. However, when the key surfaces need to be backlit, or the surface is curved or warped, the PCB cannot be mounted directly behind the display. For this situation, we recommend the use of a separate sensor film in which the sensor surfaces are screen-printed onto a polyester film and connected to the electronics via the membrane ribbon cable. The LEDs are also fitted on the PCB, which is at a defined distance from the front, in order to illuminate all the surface areas of the keys.