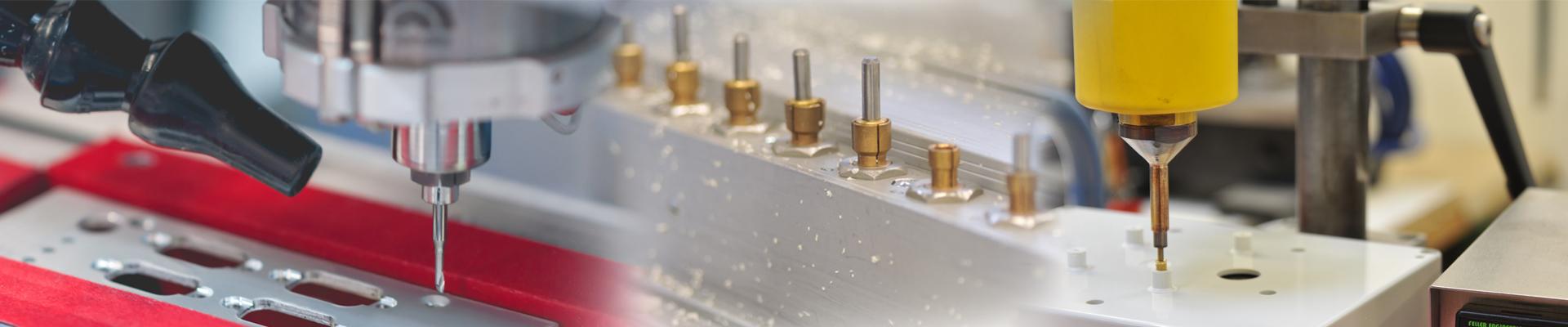

General Hints for Machining Enclosures

Milling, Drilling

When machining plastic enclosures the tools must be cooled with oil-free air. Drilling coolants and separators can cause splitting and tearing. When using separators containing silicon subsequent imprinting and lacquering is not possible as the laxquer would not adhere properly. In case of doubt please ask for information.

Our machining service excludes these risks.

Note: The standard milling radius is 1.5 mm. On request the radius can be minimised to 0.5 mm for a small additional charge.

Tolerances (DIN ISO 2768-m)

Nominal dimension ranges

| over 0,5 to 3 | over 3 to 6 | over 6 to 30 | over 30 to 120 | over 120 to 400 | over 400 to 1000 |

| ± 0,1 | ± 0,1 | ± 0,2 | ± 0,3 | ± 0,5 | ± 0,8 |

Punching

When plastic parts are punched corners can tear or break.

Gluing

The quality for a glued joint depends on the materials to be glued, the size of the glued area and the adhesive used.

The following should be born in mind:

- Only glue the same materials (e.g. ABS to ABS)

- Glue as large an area as possible

- Use suitable glues and follow the technical instructions

- Test the adhesion under conditions of use, such as temperature, strain etc. before starting series production.

General Instructions for Machining Aluminium Enclosures

Please make sure that all residues of any coolants or lubricants used in machining are removed if plastic parts must be attached to aluminium enclosures (e.g. plastic cable glands, adapters, plugs, etc.). Coolants and lubricants can cause plastic parts to become brittle and split. Also, remember that when aluminium castings are machined, enclosed air bubbles, known as shrinkage holes, can be revealed. The casting process and alloys we use result in very few shrinkage holes.

Instructions for Machining Aluminium Plates

For reasons of design and stability, we offer aluminium front panels for many of our plastic enclosures. These panels are cut from anodised plate material, so the surfaces have an anodised layer, but the cut edges do not. Please remember that screen-printing or tampon printing on the anodised layer may not always adhere properly. When machining and imprinting front panels to customer specifications, we use aluminium plate material which, depending on the requirements, is only anodised after imprinting. The advantages are that all the edges are corrosion-proof, and any imprinting will not rub off.