“In addition to manufacturing the enclosure, BOPLA also carried out the machining, surface improvement and printing, manufacturing of the PCB, HMI integration and packing – everything from a single source. This all-round carefree package was very important for us. BOPLA also perfectly implemented the packing concept which we had designed specifically.”

Frank Preussner, head of materials management at Schwer + Kopka GmbH

Complete implementation – from the idea to the finished product

The ideal solution, even for small quantities

Completely individually designable and configurable – almost no limits to your ideas

Everything from a single source – from processing the enclosure to mounting the display and electronics

Your personal contact person – we give you detailed advice, keep you informed, and provide support for questions and challenges

The system integration of your enclosures is our complete service for you: we work with and on your individual requirements and ideas. That is how we manufacture a tailor-made product for you, from the idea to the fully-functioning end device. Our solutions – for your products!

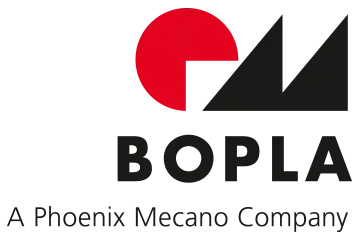

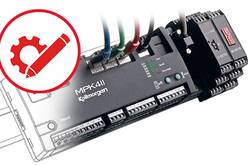

1st Enclosure

Standard enclosure or custom-designed manufacture – our enclosure is the basis for your product.

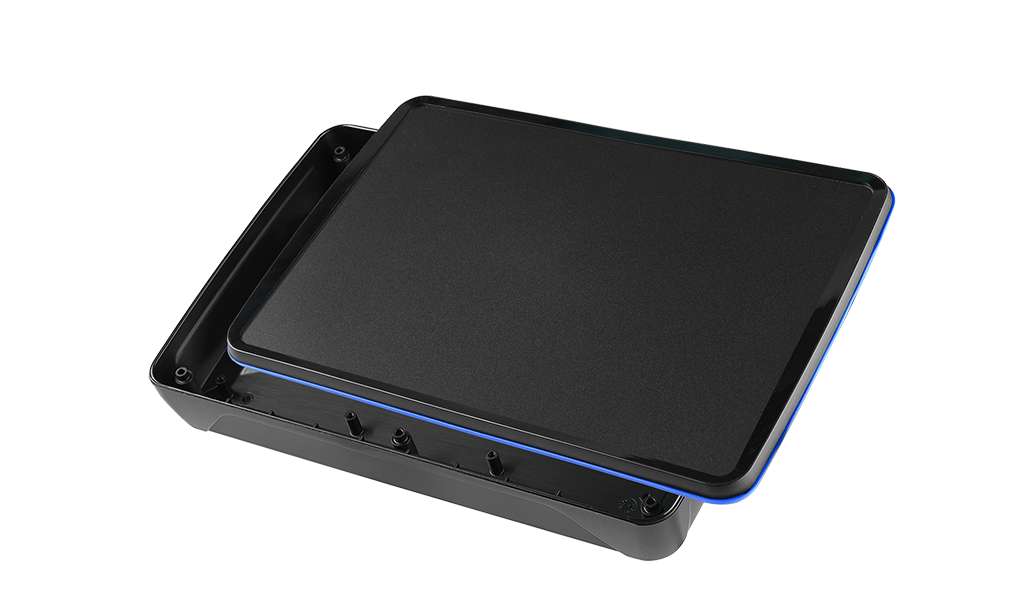

2nd Services

We process and refine your enclosure according to your wishes.

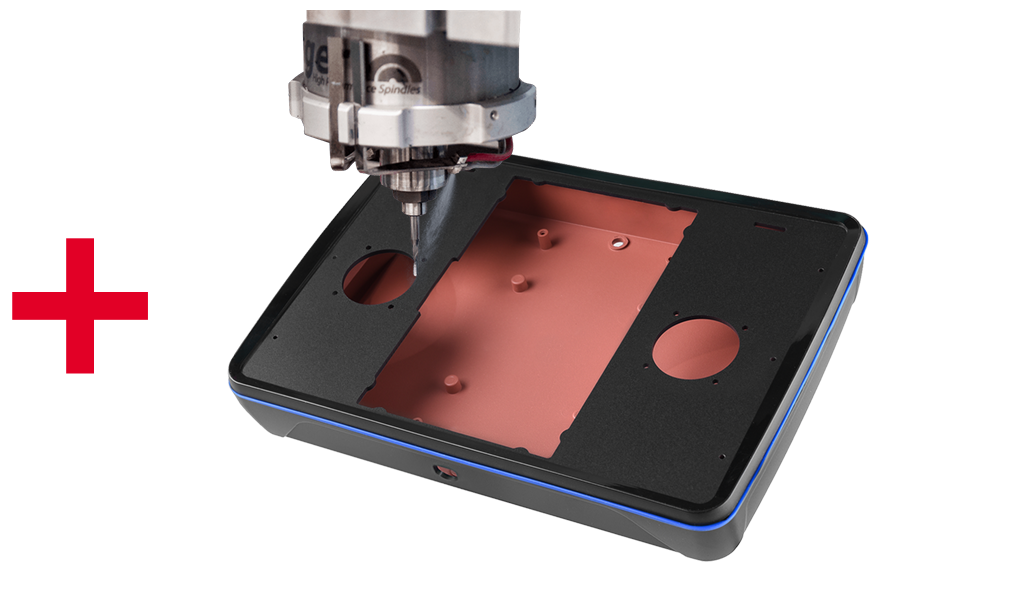

3rd HMI

Then we integrate your custom-designed membrane keypad / HMI system.

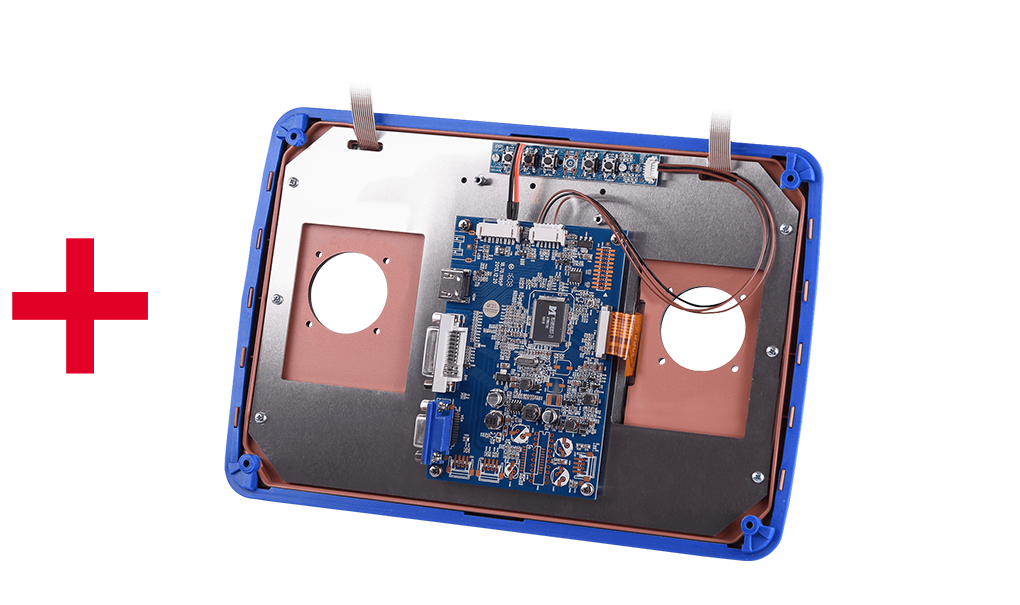

4th Electronics

We support you in the development of your electronic module through production right up to complete mounting.

Milling, drilling or cutting – we carry out the necessary alterations to ensure that you receive the product that you want. Our system integration process makes an enclosure into your product!

From company logos to device and series names to instruction markings – we give your enclosures the look that you like best.

Reduce the amount of your in-house work by allowing us to deal with the mounting, testing and packaging of your new devices!

- fast, efficient operation

- integrate in standard and also custom-designed enclosures

- capacitive or resistive unit

- can be designed according to your specifications

- suitable for the widest range of applications

- no limit to your needs!

- ideal protection for your devices

- popular in mechanically-demanding sectors

- high level of design freedom

- steel and plastic coating

- colour variations by using decor materials

- antimicrobial Autotex-AM decor foil

Video tip: an overview of our membrane keypads / HMIs

In their function as operating modules, the membrane keypads / HMIs form the interface between human beings and machines. BOPLA offers a large number of input systems to ensure that you receive optimal operability for your application, so you can choose between touch screens, front membranes, short-stroke keys or membrane keypads .

Of course, as part of the system integration process, we also offer individual solutions for your enclosures which, with regard to the membrane keypads / HMIs, conform to your ideas and requirements. In this way, maximum precision and functionality in your intended application are guaranteed.

- fast, efficient operation

- integrate in standard and also custom-designed enclosures

- capacitive or resistive unit

- can be designed according to your specifications

- suitable for the widest range of applications

- no limit to your needs!

- ideal protection for your devices

- popular in mechanically-demanding sectors

- high level of design freedom

- steel and plastic coating

- colour variations by using decor materials

- antimicrobial Autotex-AM decor foil

Why BOPLA is the right partner for your system integration and enclosure technology:

- For more than 50 years BOPLA has been successfully developing electronics enclosures. Thanks to our expertise, we know exactly how to inspire you.

- Customer-orientated working is very important for us at BOPLA – we work according to your exact specifications to ensure that you receive the product that you want.

- Comprehensive support – from the initial consultation to the function test on the finished device, BOPLA stays in active contact with you.

- Free samples – we manufacture samples free of charge for you so that you know exactly how well your electronics fit in the enclosure.

- Advice from our experts – we will advise and assist you on your premises, at our headquarters or online.

- The complete work process from a single source – system integration takes place exclusively on our premises, which is how we secure optimal quality standards.